Robotics and industrial automation are changing the manufacturing landscape. Manufacturers all across the world are implementing automation to become more efficient, safe, and profitable. While some advantages are apparent, there may be others that you are unaware of. All in all, it’s easy to see why so many sectors invest in industrial robots.

Industrial Robots in the Twenty-First Century

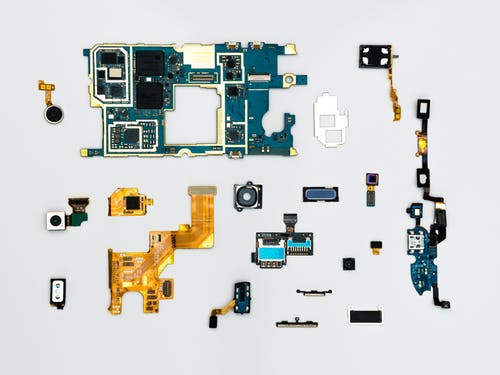

Today, industrial robots are utilized in various industries, including robotic device encapsulation, semiconductors, automobiles and plastics processing and metal forging. Almost any repetitive task, especially dangerous or difficult for humans, is excellent for a robot.

The usage of robots in the manufacturing industry is quite advantageous. Robots have typically been used for high-volume tasks, but as technology advances and costs decrease, new possibilities and opportunities for medium and small businesses emerge.

Simultaneously, these robots help manufacturers deal with various fundamental issues, including labor shortages, global market competitiveness, and safety.

Reasons To Invest In Industrial Robots

If you’re debating whether or not robots can benefit your company, consider the following compelling arguments.

Efficiency

Industrial robots can complete them faster and more efficiently because they are conceived and built to execute jobs with higher accuracy than humans. Together with the fact that they are utilized to automate operations that would have previously required a large amount of time and resources, industrial robots help to increase the efficiency of production lines.

Quality

An industrial robotic soldering solution can produce superior quality products due to their increased accuracy, saving the time required for quality control and guaranteeing that quality requirements are met.

Safety

Some tasks are deemed too dangerous, difficult, or tedious for people to complete. The result of this is that robots will be in a position to take their place. Industrial robots can significantly improve working conditions and safety in factories and manufacturing plants.

Profitability

Industrial robots improve the efficiency of your operation by decreasing the resources and time needed to complete it while also producing higher-quality goods, leading to increased profitability and lower cost per product. In the long term, industrial robots like a robotic primer application for auto glass can save you money.

Productivity

Distractions occur as human breaks are required during the working day, and attention spans diminish. On the other hand, robots can operate indefinitely and effectively. When one critical person is replaced with a robot, who works the same hours as the human, the production line’s output increases by 40% on average. Furthermore, robots do not take vacations or miss work due to unforeseen circumstances.

Prestige

Robots are wonderful as a marketing tool, enhancing your brand image, and are frequently used merely for PR if it isn’t enough to “wow” your clients by working at the cutting edge of your industry.

Conclusion

All of these advantages help businesses stay competitive in today’s global market. You may assume that buying a robot is out of your financial reach or beyond your comprehension. There are, however, several options and resources available to assist you in saving money and getting up and running quickly. Dealing with a qualified integrator who has worked with various small and large manufacturing facilities can be incredibly beneficial to your company’s growth.